5 Innovative Industrial Networking Features to Help You Improve OEE

With manufacturers trying to meet customer demands for personalized products, equipment builders are including motion control solutions that can address manufacturers’ OEE goals. Focusing on a motion-centric OEE solution will grow profits maintaining efficient manufacturing while making frequent production line changes to customize products. In our blog post: Deciphering Between OEE and IIoT, we share how to start networked OEE projects. SANMOTION products are built to support equipment builders looking for networked motion control systems. Networked motion control systems are an essential component to improve each of OEE’s variables for productivity beyond just downtime concerns.

OEE is a quantitative measurement of Overall Equipment Effectiveness that takes all of the following into account:

• Performance – the ratio of actual run rate / ideal run rate

• Quality – the ratio of good units / total units

• Machine Availability – the ratio of operating time / planned production time

The traditional approach for optimizing OEE on a production line focuses heavily on maintenance in an attempt to limit downtime. With the advent of Industrial IoT (IIoT), an alternate and potentially more successful approach is to focus on productive outcomes. The key is to not only focus on keeping the machine running, which directly affects the Machine Availability variable in OEE, but to address all of the OEE variables with motion control solutions that are flexible enough to allow for new production line innovations.

Along with convenient servo

Along with convenient servo  A critical feature of the EtherCAT servo system is its high-speed data transmission. OEE Performance and Quality variables are improved with multi-axes synchronization that are capable of communicating with other EtherCAT enabled devices for production processes.

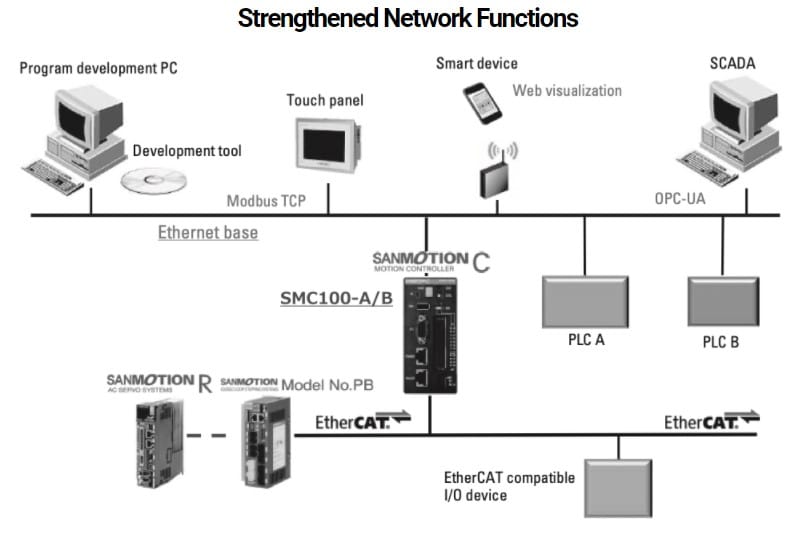

A critical feature of the EtherCAT servo system is its high-speed data transmission. OEE Performance and Quality variables are improved with multi-axes synchronization that are capable of communicating with other EtherCAT enabled devices for production processes. Motion-centric automation data is accessible via OPC-UA on SANMOTION C Series

Motion-centric automation data is accessible via OPC-UA on SANMOTION C Series

Recent Comments